CASE HISTORY ———— 17 June 2019

Centro libri and Sitma

—————— A COMPLETE, HIGHLY AUTOMATED SYSTEM FOR DISTRIBUTING BOOKS

Business unit E-logistic Sitma

Centro Libri is a company in Brescia, Italy who, since 1976 has been distributing books throughout Italy and has recently decided to buy a Sitma Speedy Sort, along with a packaging machine. The Sitma solution has raised automation in the company and optimised warehouse management, but remains flexible and extremely profitable.

—————— A SPECIAL MACHINE TO AUTOMATE ALL STAGES IN DISTRIBUTION AND RETURN

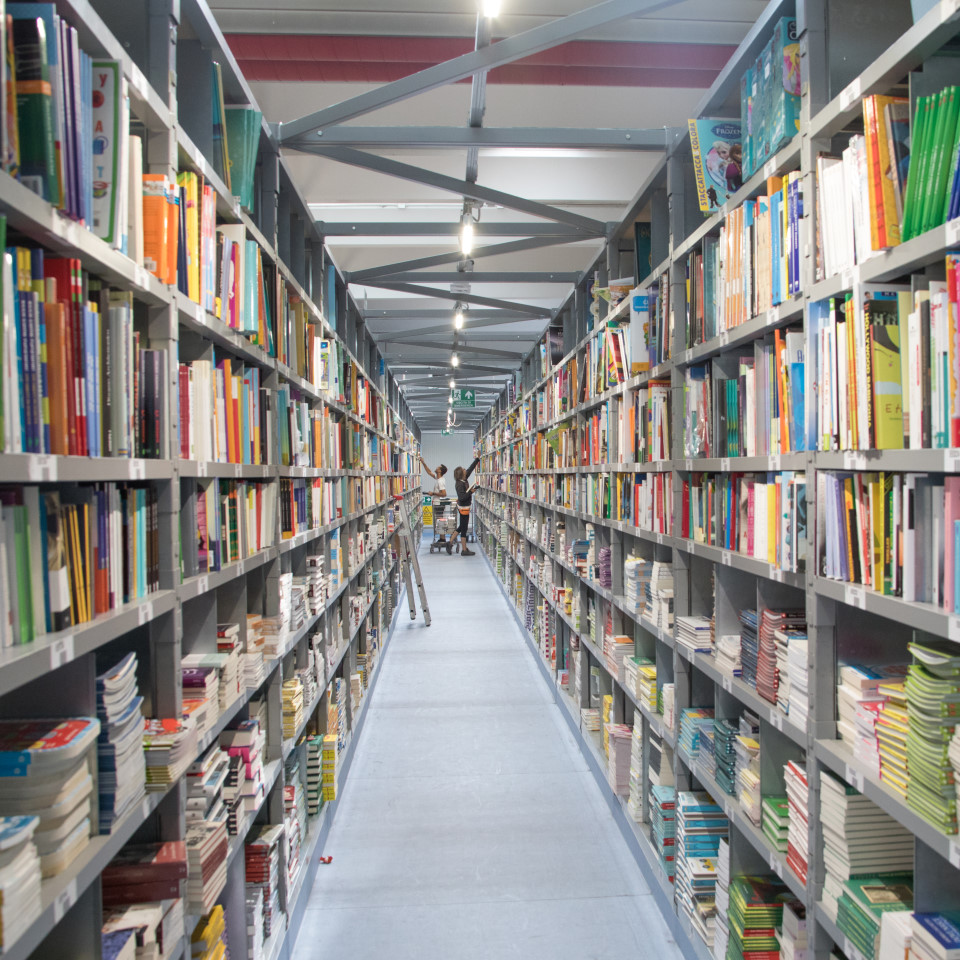

This partnership between Sitma and Centro Libri arose after this company said they needed to improve delivery efficiency during the distribution of books and when dealing with returns. Among the booksellers supplied by Centro Libri there are many classical bookshops, but also e-commerce companies such as Amazon or IBS, and many townships which deliver schoolbooks to families. Overall, there are more than 5,000 customers ordering approximately 1,000 books a day. These are housed in a warehouse containing more than 10,000 books.

Until late 2017, this operation was all done manually by an operator who took books directly off shelves and put them into cardboard boxes. To accelerate and optimize this process, in late 2017 Centro Libri bought some new machinery for the automatic sorting and packaging of books for delivery. As well as improving sorting, the Sitma system (speedy sort) also means that mass picking is much faster. This has greatly improved warehouse management. The same machine can identify any books being returned by booksellers.

—————— THE SYSTEM: WHAT DOES IT DO, AND HOW DOES IT DO IT?

Sitma Speedy Sort is a book sorter, and has several stages. At the start is an ergonomic feeding system with bays where products are positioned manually and are then taken up a ramp to the sorting section. Conveyor belts are fitted with CCTVs which they use to read barcodes and book titles. There is also a special exit for any books it cannot identify.

Books are then fed into a carousel module with 278 pockets. These pockets, which are always turning, open at the bottom when they come up to the outlet they have been assigned to, and deposit their books onto a gentle slope so they are not damaged. They then pass into the packaging system. This is a section where boxes are filled manually from trolleys containing sorted books, a weighing section, and a system which prints packing lists. There is also a unit to tape the boxes closed, a binder, a printer, and a labeler. The system is also fitted with CCTVs for identifying boxes during the various stages of packaging, which read the barcodes affixed when the boxes are being filled.

—————— EFFICIENCY AND FLEXIBILITY IN DISTRIBUTION AND RETURNS

This machine can handle up to 180 books per minute, or 10,800 books per hour. This means a total of 80-100,000 books per day can be sorted. Books being returned are put into the sorter, along with the customer ID. The system recognizes books and credits them to the customer who has returned them. They are then sorted to a series of outlets by category, so they can be returned very simply to the warehouse. For outbound deliveries, the delivery system used by Centro Libri assigns books to individual customers or according to a series of orders. For orders placed by large customers, the sorter makes a static association: one or more exits are set aside for specific customers, and this applies over a whole batch of deliveries. For orders placed by small or average customers, a more dynamic association is preferred: the various book exits can be changed. When orders for these customers have been completed, an operator picks up a carriage and it takes it to the packaging area. The exit is then free, and can be associated with a new customer. Carriages are filled in three separate ways, which can be selected as required.

The first is single-customer mixing, which mixes a series of books in one carriage for one customer. When they reached the filling area, operators put these books into boxes until they have emptied the carriage. These books are given one docket for the whole delivery. Another category is multi-customer mixing, which places books for several customers in the same carriage, and then this is used to fill separate boxes for individual customers in the packaging area by examining each and every book individually. The third category is stratified management: here, one carriage is associated with one customer. Once the number of books deposited is enough to fill a box, a signal tells the operator who puts a separator in the carriage. And so it continues until the carriage has been filled. In this way a customer receives boxes, and knows exactly what they contain. This can be extremely useful when delivery times are very short, such as happens with e-commerce: transfer times are much quicker, and warehousing is much less important.