———— OVERVIEW

Sustainability is today a key driver for consumers when making a purchase decision. The judgment goes beyond the product itself and includes a multitude of factors, such as:

1. how the product was produced and the overall generated waste

2. can it be reused (single use vs multi-purpose)

3. its packaging, oversize vs right size, as well as its material (recyclable vs non-recyclable)

4. its journey from the factory to the final destination, CO2 consumption and pollution

When looking at the publishing segment (such as books, catalogues and magazines), the printing industry has focused for over a decade on reducing the waste with unsold production through the adoption of “print on demand” concepts. Book on demand production is today a well-established and growing sector leveraging on digital print and inkjet technology. Tecnau pioneered single-copy book production with its smart finishing technologies enabling high volumes of single copies and print to orders, thereby minimizing waste. To further expand sustainable options for book printers, with the acquisition of Sitma, Tecnau has broadened its offerings to include personalized and protective right-size jacket making systems, as well as pack-to-size sustainable packaging and smart sortation systems for efficient low-carbon distribution.

———— Tecnau Print Finishing on Demand solutions

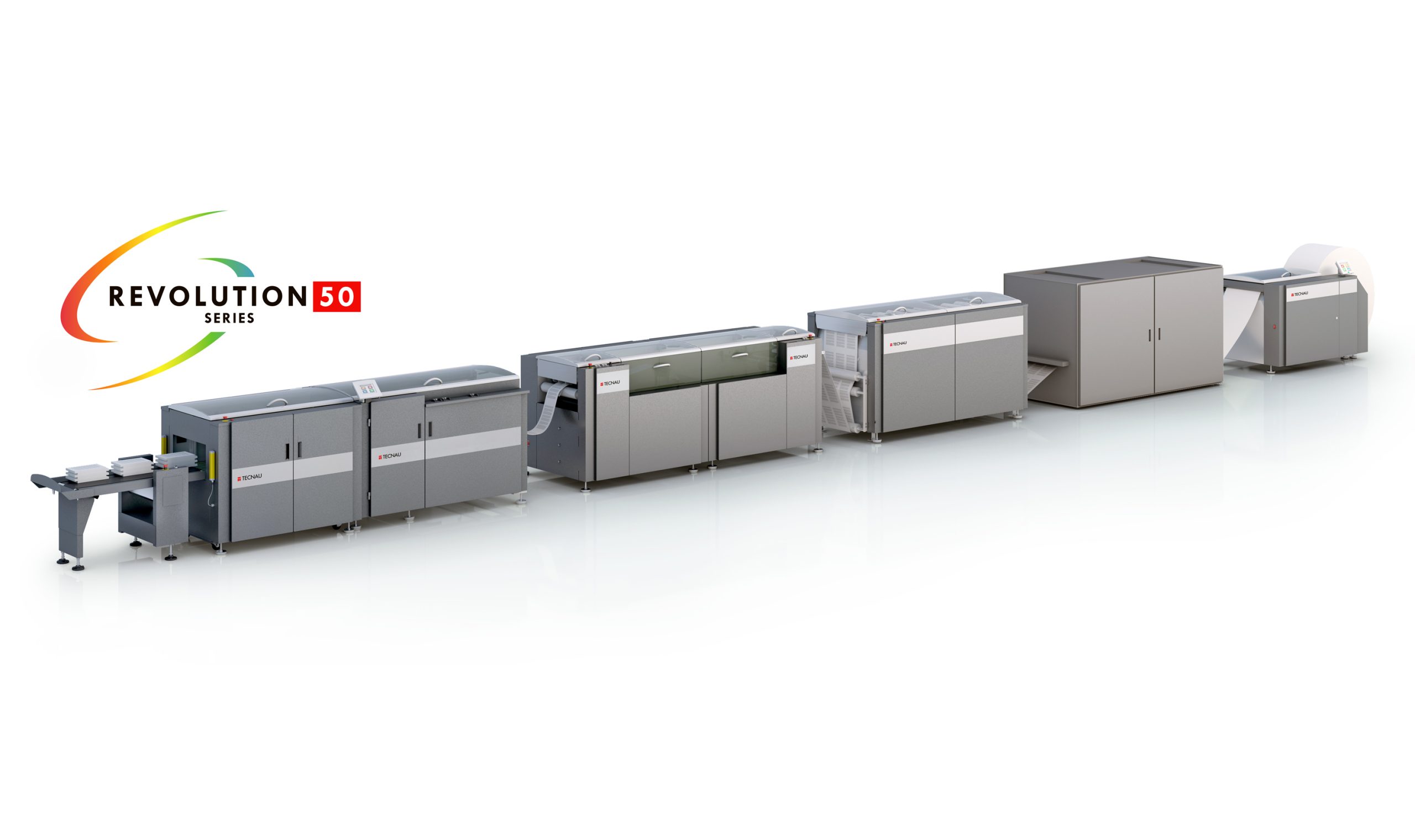

With an extensive product range for continuous web and cut-sheet printing, Tecnau has consistently developed solutions that facilitate the production of small batches or even single copies with highly automated and flexible systems, along with quick or “on the fly” format changes to reduce downtime and the waste typically associated with application changes.

———— Book-block production

In the continuous feed segment, the StreamFolder 5152 book-block making solution features the StreamFolder f50 plow folder with enhanced automation available for easy and fast job changeovers and reliable, consistent production. The Stacker s52 features jogging for top-quality stacking and optional multi-position tack gluing for smooth signature handling.

In the cut-sheet segment, the company has also recently introduced BookReady (2023 EDP Award Winner), a completely automated system for short-run and book-on-demand production inline to sheetfed digital printers with on-the-fly application change at speed and without any manual intervention.

———— Finished book production

Tecnau’s Libra solutions for the publishing sector are the real workhorse of this production concept as they offer the possibility to produce completely different books in single copies at the same costs and productivity of longer runs. On-the-fly format changes, the elimination of makeready times, and the integration of all system components taking a printed roll down to a finished book, allow printers to produce only the quantities actually needed based on the quantities already sold.

———— Sitma right-size jacket maker

Sitma’s WM10 right size jacket maker is the ideal solution to produce protective covers (jackets) to extend the life of the book beyond the first user, especially for schoolbooks. Thanks to an integrated size scanner, the WM10 produces high quality right size jackets with fully automated changeover, book by book. The system also offers the possibility to add an integrated inkjet printer to personalize the cover with information such as student name, school or logos, adding value and generating an unique service for extra revenue sources.

———— Sitma pack-to-size solutions

After books are produced, they have to go to packing to get prepared for shipment.

Creating customized, compact packages offers a two-fold advantage: it streamlines packaging material, reducing the amount of packaging product that must be disposed of at the end at the customer’s expense, and facilitates easier transport along the entire supply chain. This keeps “empty transport” to a minimum and optimizes vehicles’ loading capacity, significantly reducing the overall carbon footprint. Sitma packaging is equipped with easy open and resealable systems, so the same packaging can be used for returns.

Sitma’s pack-to-size solutions includes E-wrap, FastPack and FastPack Plus.

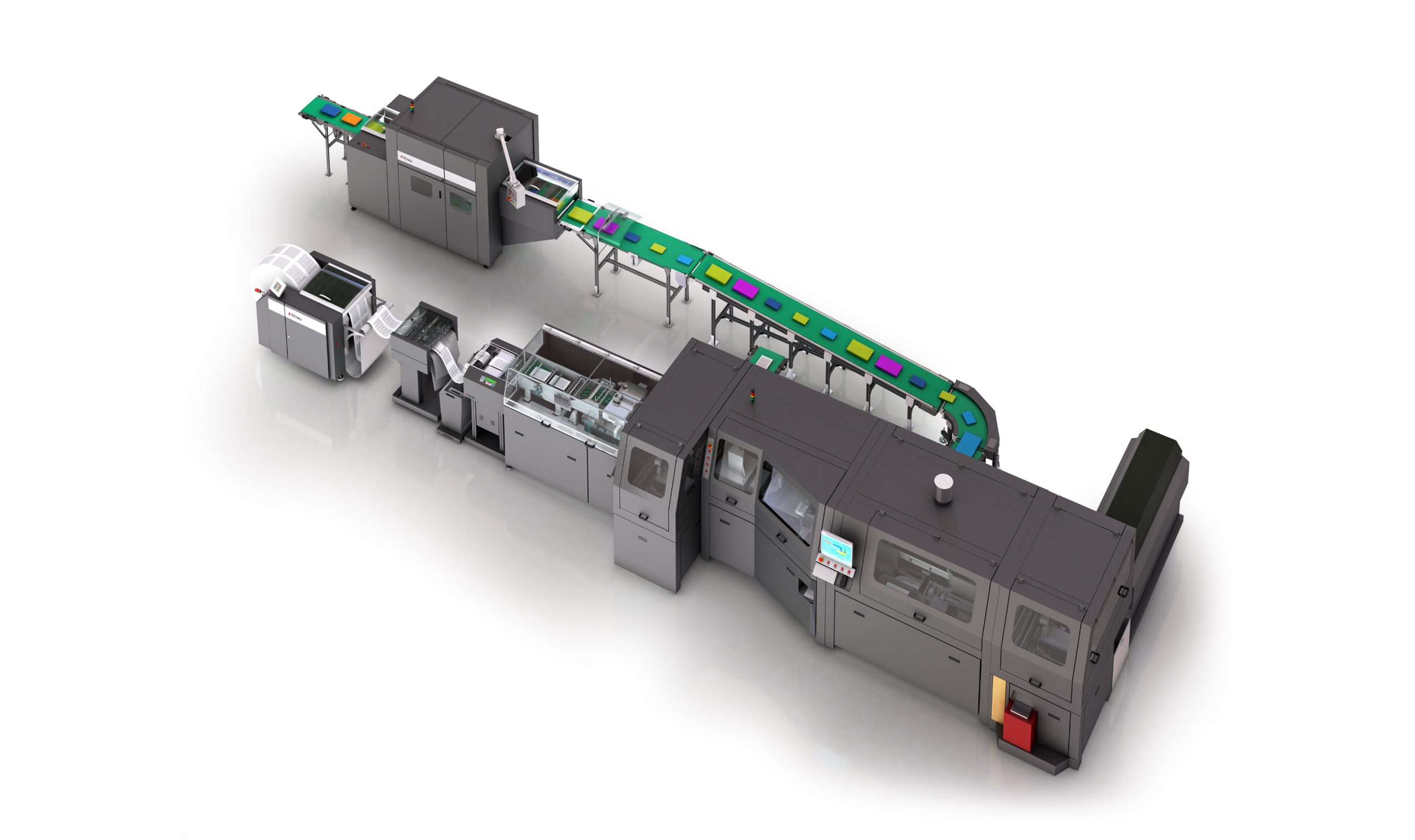

———— Smart sortation solutions

After books are packed, sorting is the next step in the delivery process. Sortation refers to the process of categorizing and arranging items based on specific criteria. Benefits of automated sortation include:

1.Efficiency: Sortation improves operational efficiency by organizing ordered products into predefined categories. This reduces the time and effort required to locate and process specific items, leading to faster throughput and reduced operational costs.

2.Improved Accuracy: Automated sortation minimizes errors that may arise during manual sorting. Automation ensures that items are correctly categorized, reducing the chances of shipping incorrect products.

3.Enhanced Customer Experience: Fast and accurate order processing leads to improved customer satisfaction. Customers receive their orders quickly and correctly, leading to repeat business and positive reviews.

4.Reduced Labor Costs: automated sortation systems require fewer human workers for repetitive sorting tasks, leading to reduced labor costs and improved allocation of human resources for more value-added tasks.

5.Optimized Resource Utilization: sortation plays a key role in optimizing the use of resources such as storage space and transportation vehicles. By grouping items with similar characteristics, it allows more efficient use of space and enhances load optimization.

Sitma’s sortation solutions includes Easy Sort, Speedy Sort and Symphony Sort.